Ordering and Technical Details

HOW TO ORDER

Our ordering process is always with a personal representative that will take you through the whole ordering process to ensure your needs are well met!

First choose your desired garments either through our website, catalog or via contact with one of our product specialists ([email protected]) along with a general quantity range of each item, then a custom quote will be generated for your review. Pricing is quantity driven, so the more you order per garment style (sizing irrelevant) the better price break you receive, we do have a minimum of at least 5 items per style. One offs can be done at a special charge.

Once a decision is made on which garments you would like to order the art process begins. If you have a question on product or would like to see a sample, please contact your Outer Circle rep as we are here to help. We know there is nothing like seeing in person our superior fabrics and garment construction as well as the high quality inks we use for our dye sublimation process. Fit kits can also be ordered to ensure proper fit of garments using a credit card to hold until fit kit is returned. Fit kits will need to be returned in order to release your order for shipping, if not returned a charge will be made on your credit card to cover the cost of the garments.

- We need 4 things to start an order:

1) CIS (client information sheet) filled out and sent in

2) Logos supplied and Art Approved

3) 50% deposit on the total estimated order

4) Sizes and quantities finalized

We have a full in house design team that can design anything to your taste, or we can work with a design submitted from you if you have your own graphics. We will send you a digital mock up for your approval within 1-5 business days. We have a full in house design team that is capable of taking a sketch, drawing or fully rendered graphical layout, and translate it into the Outer Circle Apparel line.

There are no set up charges (exceptions are for embroidery and silk screening processes) and artwork is billed at the rate of $45 per hour. As a courtesy we waive the first hour! If you have specific colors we work only with PMS colors (CMYK values are not accepted for dye sublimation) so please provide those along with any logo size specifications that you may need on your garments. We work with Adobe Illustrator and that is our preferred method of artwork received but can work with any vector format such as eps or pdf as long as it originate as a vector file. Please allow a few weeks to dial in your design to your exact specifications. Once art is approved you will be given a general delivery week- if you have a specific date please share that with your personal OC rep ahead of time to ensure proper delivery schedules.

We need 4 things from you to start the countdown of your custom order!

1) CIS (client information sheet) filled out and sent in

2) Art Approved

3) 50% deposit on the total estimated order

4) Sizes and quantities finalized

We do require a 50% deposit based on your total estimated order to start any artwork process. We accept Visa/Master Card, ACH and Check as forms of payment and final sum is due upon shipping your order. Note your order will not start in the production que until the deposit is received.

Production time frames can very during the time of year, though our standard time frame is 4 weeks. The start of the race season can cause the turnaround times to jump several weeks due to the volume of orders. It is best to start the design process with this in mind and keep in mind that artwork can take a few weeks in itself to dial in.

Even if sponsorships are not solidified, we can start the basic design concept and a planned slot with your desired delivery date in the production schedule. It is important to keep to your deadlines that will be supplied after your desired delivery date is punched in our schedule, if these are not met it can push your delivery date back. We can be flexible as are manufacturing facility is completely USA based, but there are times that the scheduled may be at capacity and may not allow us to accommodate a rush situation. Please inform your Outer Circle rep of any critical dates to ensure they can be met, and submit payment as soon as possible to hold your production slot. Rush orders can be subject to an additional charge if below our standard time frame.

There are 4 basic steps to production after artwork is approved and colors are specified:

1) Laying up artworks for production and dialing in colors

2) Printing- art is printed on paper for sublimation process

3) Heat transferring- ink is sublimated from the paper

4) Assembly- All sublimated pieces are then constructed into a final garment, they are then subject to quality control to ensure there are no damaged or printing problems.

PROPERTIES OF CARBON FIBER TECHNOLOGY

TECHNICAL DETAILS

What we do is very unique, we work with a Carbon Fiber Technology in our fabric line up. It is actual carbon fiber yarn woven into the fabric to help with the performance capabilities.

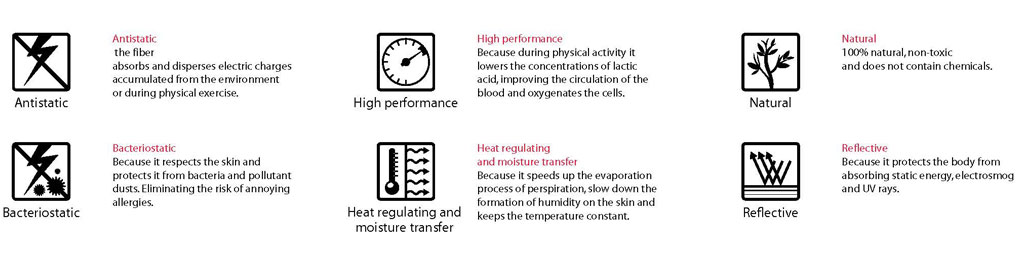

Besides the "cool factor" Carbon Fiber actually is the highest performing fabric due to its natural ability to have superior moisture wicking and breathability, it supports active blood flow, it’s anti conductive properties and last but not least, it is naturally anti-microbial, which means it’s properties ward off odors that can be created by sweat that lock into the fabric! Basically it takes our top of the line performance fabrics and design and enhances its capabilities and desired look to make our garments overall the best on the market!

Here at Outer Circle we are as passionate about being built in this great country of ours as much as we are about motorsports. We believe in boosting our economy and have over 35 years of experiences in custom performance apparel. We are proud to say that 100% of all our custom apparel is sublimated, and constructed in the USA. We ship internationally as well, so no matter where you are you can work with us to outfit you in the most technological apparel out there!

Performance apparel uses fabrics that are designed to do just that, perform! A fabric that actually works for you. It is designed to either keep you cool or in some cases warm, but always breathable so you don't feel like you are trapped in your own personal sauna!

It transports moisture away from your skin and quickly evaporates for maximum moisture control, which helps regulate normal body temperature. There are different levels of performance of each fabric, and we specifically designed our apparel with that in mind. Using specific levels of performance fabrics for certain areas of the body that need maximum performance and get the job done as any top performer does!

Our dye sublimation printing process involves the use of a special dye ink that sublimates when it is introduced to high temperatures.

This ink is first printed onto a transfer paper via a digital printer and then this printed image is transferred onto a cut garment piece using heat and pressure. The ink reacts to the heat by “sublimating” in that it changes from a solid state into a gas state (thereby skipping the liquid state entirely). The dye then bonds with the fabric to create a vivid, texture-less, and permanent dye print. This process not only yields vivid print colors that are wash-fast and durable but it also allows you to print photographic or color-complex graphics accurately.

Pantone colors or PMS numbers are an industry standard. It is a universal system used to code and ensure proper color matching. Because computer monitors are dictated by screen resolution, not one screen will have a particular graphic look the same. Things don't always print and transfer the way they look on the screen. So with that we use the PMS number system to ensure we are all choosing the same/proper colors. Pantone books are typically available to purchase or view at arts and crafts stores if a reference is needed.

We have several stock garments and other CF-1 custom items that can be full embroidery or a hybrid of sublimation and embroidery. Embroidery is stitching logos on fabrics using thread that cannot be sublimated or if it is preferred on your garment, and can only be placed on areas where a stitch head can be placed (there are some restrictions). Logos either need to be supplied in a digitized embroidery file or in a vector format so we can then digitize and ready then for embroidery. Digitizing fees are $60 per logo. PMS colors are also needed to match thread colors. You will be given a quote once you have determined how many logos, size and placement for each style of garment, embroidery is charged by stitch count.

Silk screening is used on stock items and can have multiple areas of logos colors etc. Keep in mind pricing is based on how many locations are being printed, how large the printed are is, and how many colors are being used. For silk screening there are screens that are made for each color that is used for each graphic that is printed, and a $25 screen charge is incurred for each screen that is made. Please contact us for a quote.